Test-Tech Develop New Method For Assessing Papers For Dry Toner Digital Press Printing

Transfer Current Window Testing

There are many paper factors that affect print quality on dry toner digital presses including volume and surface resistivity, moisture content, salt content and type, sheet structure, roughness. The problem with using measurements like these to predict print quality is that they interact with each other, very importantly with the press set up, particularly the transfer current. Unless you take the press transfer current into account, the results are likely to be misleading. With this in mind we have developed a test which allows us to assess the print quality of a paper across a wide range of transfer current settings and then express the results as a total print quality score and a transfer current window in which acceptable print quality is achieved. These measurement are very useful print performance indicators, the total print quality score relates to the overall print quality of the paper and the transfer window score relates to how forgiving the paper will be in dealing with presses of varying set up or type. If you wish to develop paper or paper additives for dry toner systems then this type of assessment will prove invaluable.

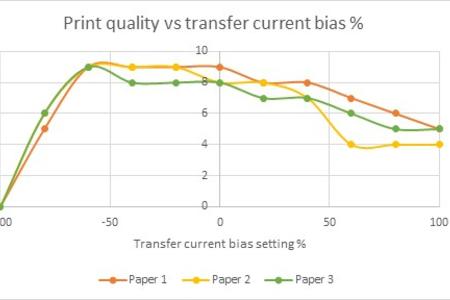

Example: A manufacturer of premium coated papers wanted to benchmark the performance of their own and competitor products. Transfer current window testing was performed and the following summary graph generated

In this chart a score of seven or above represents acceptable print quality. Papers 1 and 3 achieve acceptable print quality over a larger range of transfer currents compared to paper 2, whereas papers 1 and 2 achieve better overall print quality compared to paper 3. Also, the peak of print quality is not at the same transfer current for each paper and this is significant because presses are set up with default transfer current settings (in this case at 0) which may or may not coincide with the peak of paper performance.

With this information the paper manufacturer not only received extremely valuable competitive benchmarking data but can also use the data to help develop papers by understanding what paper properties are the key levers in achieving best print quality and the widest transfer current window.